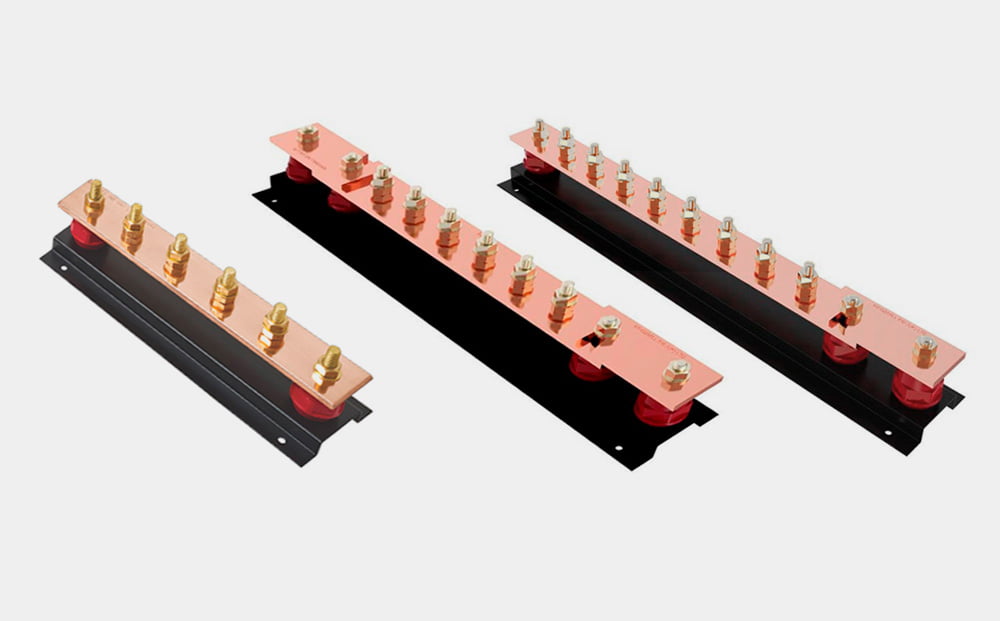

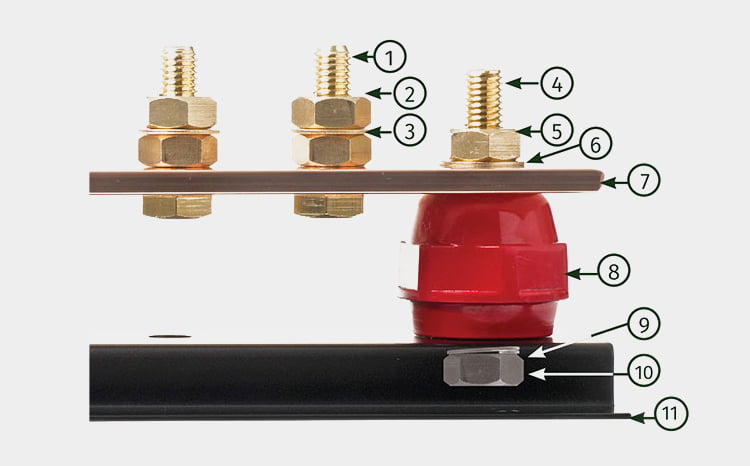

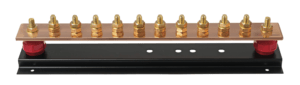

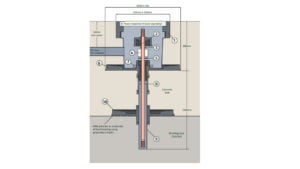

Earth Bars

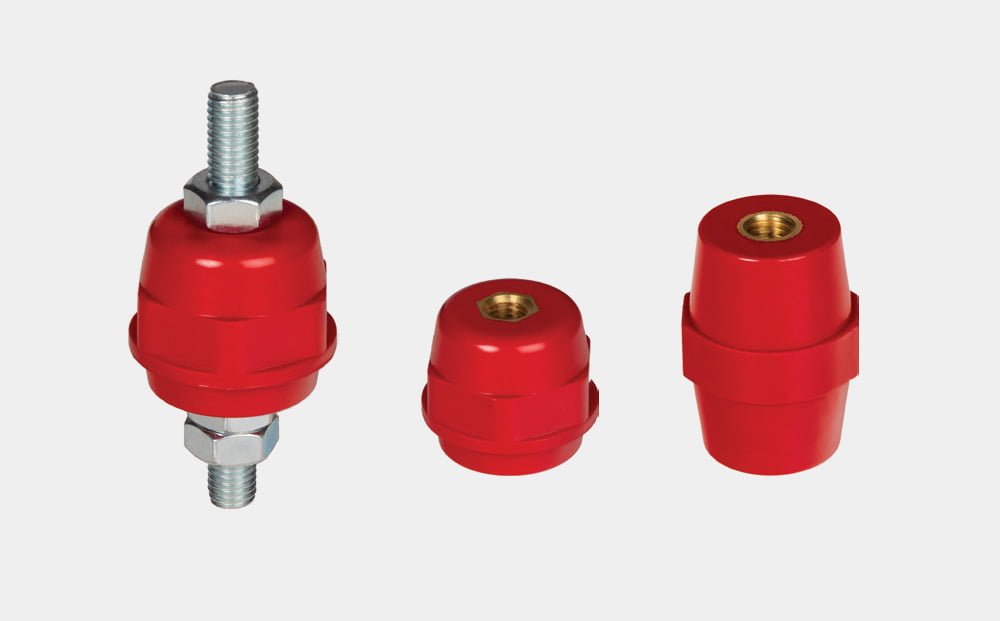

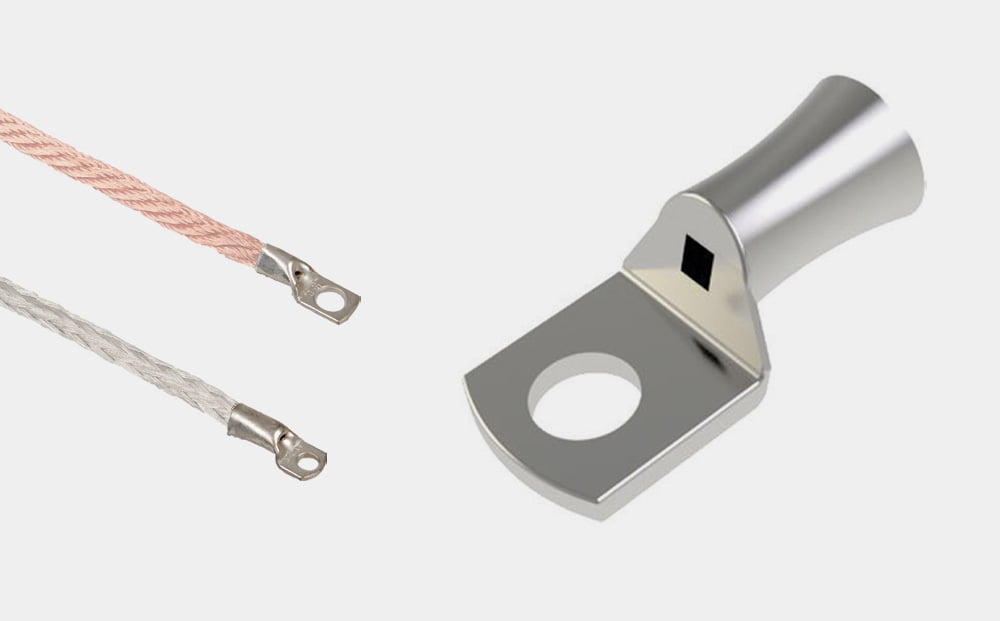

Earth Bars are used in Lightning Protection Systems and Earth Systems to collect a group of “bonding and earth continuity conductors” together and connect them to the exterior bars that enable disconnection for periodic testing. Our range includes standard, single-linked and twin-linked Earth Bars and can also manufacture to your own specifications.